Soldering Copper Pipes

While soldering Allen plumbing copper pipes looks difficult, with an understanding on some basics and a little practice, anyone with the patience and the proper tools can do it.

While soldering Allen plumbing copper pipes looks difficult, with an understanding on some basics and a little practice, anyone with the patience and the proper tools can do it.

Sweated Joint

A pipe joint that is soldered is sometimes called a sweated joint. It is done by heating either copper or brass fittings to a point that metal solder melts and creates a seal. The first step is to clean all fittings and pipe. This commonly is done with an emery cloth or wire brush. The pipe must be completely dry. Any moisture that remains in the pipe will cause insufficient or uneven heating.

Prepare for Soldering

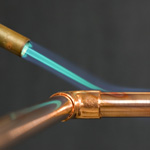

Once clean of all grease and dirt, apply a thin layer of soldering paste. This paste will assist the solder to flow into the joint. Assemble the fitting to the pipe and wipe clean any excess paste. Next is the heating process. It’s very important to use extreme care when heating the pipe with a propane torch. Protect surrounding areas with non-flammable materials such as heavy gauge sheet metal.

Heating

With the area protected, have your solder ready and begin heating the pipe and fitting evenly. Be certain to heat all sides. Begin to apply the solder to the joint. When the temperature of the pipe and fitting is sufficient, the solder will melt into the joint. Remove the flame briefly then proceed to the next joint. If the pipe is no longer hot enough to melt the solder, repeat the process. After the joint cools briefly, clean away excess solder with a dry cloth. Remember the pipe and joint is extremely hot. Allow the area to cool and then test your joint by turning on the water.

With practice any homeowner with the necessary tools can solder a pipe joint. However, if this is a project you do not want to attempt, we are ready to send an experienced Allen plumber today.